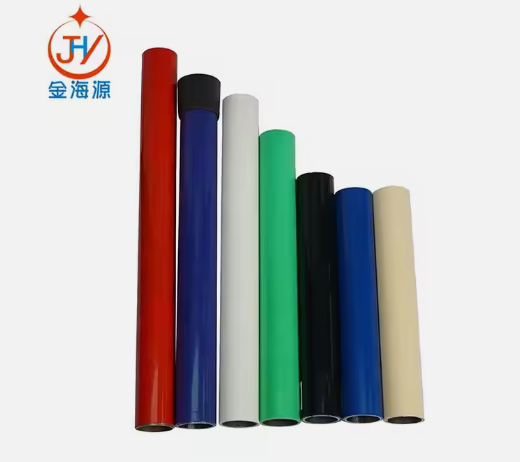

Materials of lean pipes The main materials of lean pipes include steel, stainless steel and aluminum alloy. The first generation of steel lean pipe is mainly made of steel, covered with plastic outer layer and anti-corrosion coating on the inner wall. The advantages of steel lean pipe include simple processing, low price, suitable for all walks of life, can compress the cost of .

Stainless steel lean pipe The second generation lean pipe is made of stainless steel, usually using colored stainless steel or chrome plating process. The advantages of stainless steel lean pipe include high strength, wear resistance, corrosion and corrosion prevention, suitable for a variety of industrial environments .

Aluminum alloy lean tube The third generation of lean tube is made of aluminum alloy material, the surface after anodic oxidation treatment, anti-corrosion and rust prevention, light weight, elegant and generous appearance. The advantages of aluminum alloy lean pipe include light weight, easy loading and unloading of connections, flexible and convenient assembly, and improved working efficiency .

Structure and manufacturing process of lean tube Lean pipe (also known as wire rod) is composed of four layers: the outer layer is synthetic plastic resin (such as pvc, pe, abs), the middle layer is special polymer adhesive, the third layer is welded steel pipe, and the fourth layer is internal spraying anti-corrosion material. This structure makes the lean tube have high strength, durability, oil resistance, fire resistance and moisture resistance and easy cleaning characteristics