The use of aluminum joints and aluminum tubes can improve production efficiency as they can be quickly connected, reduce installation time, and have a certain degree of durability and stability.

Aluminum joints and aluminum tubes are commonly used in industrial and mechanical equipment, capable of withstanding high pressures and temperatures, ensuring the stability and safety of connections. In addition, the lightness and ease of processing of aluminum materials also make them more efficient in the production process.

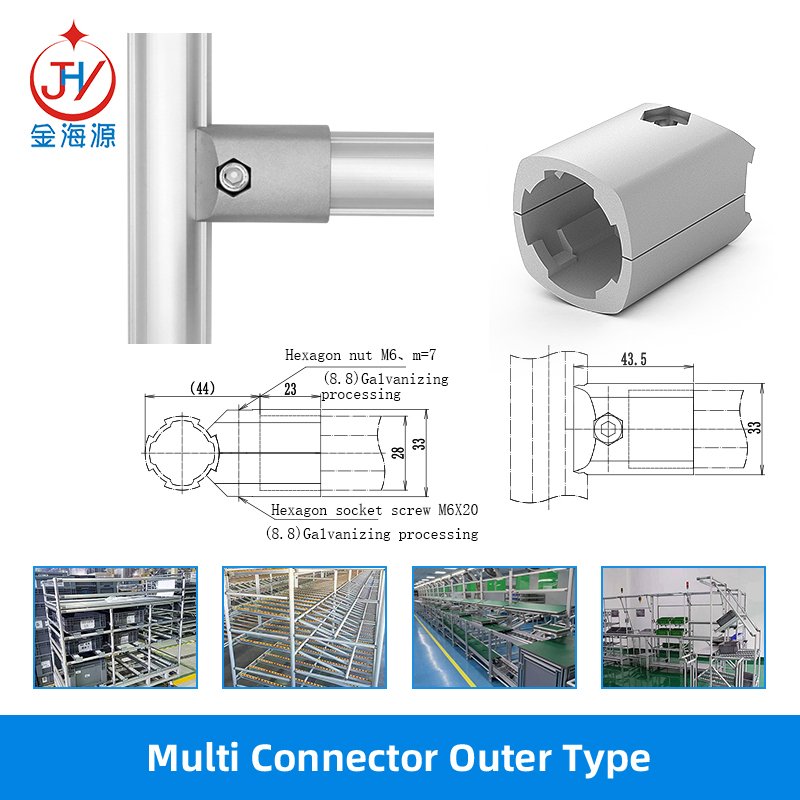

There are various connection methods for aluminum joints and aluminum tubes, including threaded connections, flange connections, and quick connect connections. Threaded connection is achieved through the tight fit of threads, suitable for situations that require frequent disassembly; Flange connection connects two pipe fittings through flanges and bolts, suitable for high-pressure and high-temperature environments;

Quick connector connections are designed with special features to make connections and disconnections very quick, making them suitable for situations that require frequent replacement or maintenance