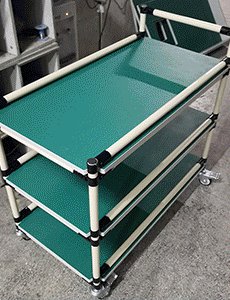

Lean tube turnover car is beautiful, generous, practical, acid-proof, alkali-resistant, oil-resistant, non-toxic and tasteless, so it has the characteristics of bending resistance, anti-aging, bearing strength, stretching, compression, tearing, high temperature, so The made wire rod turnover car can be used for both turnover and semi-finished product storage. It is light, durable and adjustable, especially for polyurethane casters. It has no damage or no trace on the clean workshop floor. In addition, because this kind of turnover car is composed of wire rods and their accessories, it is easy to install, flexible, and can control the height and size at will. It can be assembled according to your imagination and your special requirements. It is widely used in the transportation, distribution, storage, distribution and processing of SMT processing, machinery, automobiles, home appliances, light industry, electronics and other production enterprises. Feature 2:Due to the diversification of modern production products, it is necessary to constantly change the logistics station equipment and continuously adjust it during the production process. Building block components can be constructed into almost all kinds of medium and light work stations. Change is inevitable, and the standard components of the bar products make it easy to adapt to changes in the field. In line with IT production methods: Due to the diversification of modern production products, it is necessary to constantly change the logistics station equipment and continuously adjust it during the production process. Building block components can be constructed into almost all kinds of medium and light work stations. Change is inevitable, and the standard components of the bar products make it easy to adapt to changes in the field. Improve the working environment: In addition to reducing the time and necessary movement required to access parts and tools, the bar product can also help you reduce the risk of injury in the workplace, as the main components of the bar product are coated with plastic. . Scalability: The high-profit product system can design new accessories that can be matched with the original lean frame through different product requirements, and increase the use of different production methods or different stations. Reusable: The accessories of the bar products are recyclable. When the life cycle of a product or a process is completed, the structure of the bar can be changed and the original parts can be reassembled to meet the new requirements. Ergonomics: Due to the simple adjustability of the bar products, it is easy to adjust the pick-and-place height of the bar products, so that each operator is in the best working position. Continuous improvement: The wire rod product system can inspire the innovation and innovation of the employees, and the best result is to continuously improve the products and processes. The wire rod revolving car product uses the simplest industrial production concept that is easy to understand. The instrument of the wire bar shelf product does not have to consider too many precise data and structural rules except for the load description. Production line workers design and manufacture wire rod products according to their own workstation conditions. Flexibility: With a simple design, the production of lean material handling systems is flexible, allowing you to design, build and adjust to your specific needs.