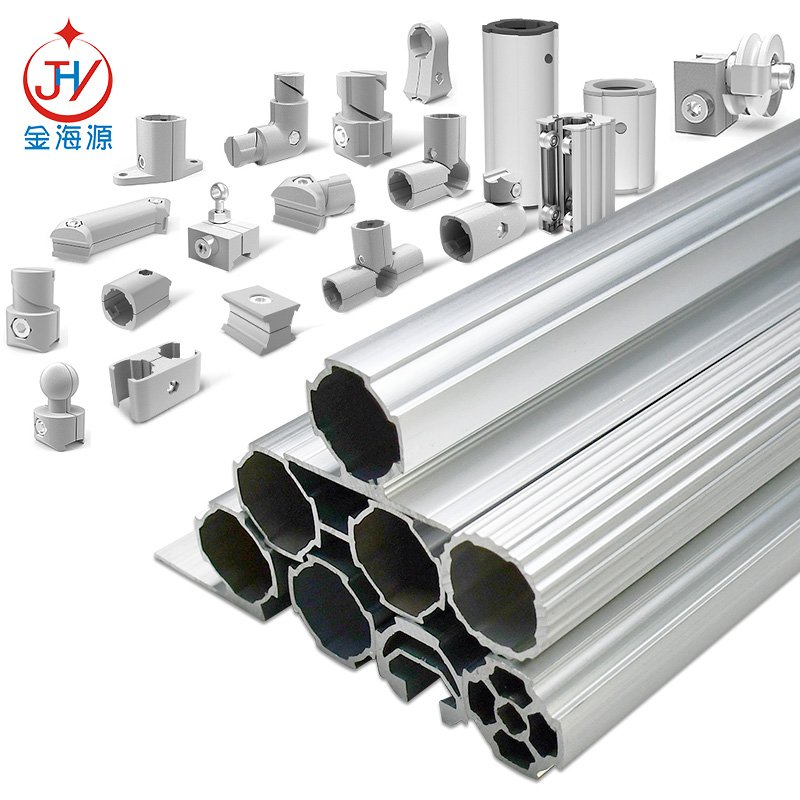

The Use Of Aluminum Tube System

Aluminum Tube System is helpful for both aerospace and industrial uses. Since aluminum supplies around three times as much quantity of metal a pound as steel goods, it’s the clear choice when weight is a vital element. Great resistance to rust allows its use without security in many surroundings. The capability of aluminum to carry […]