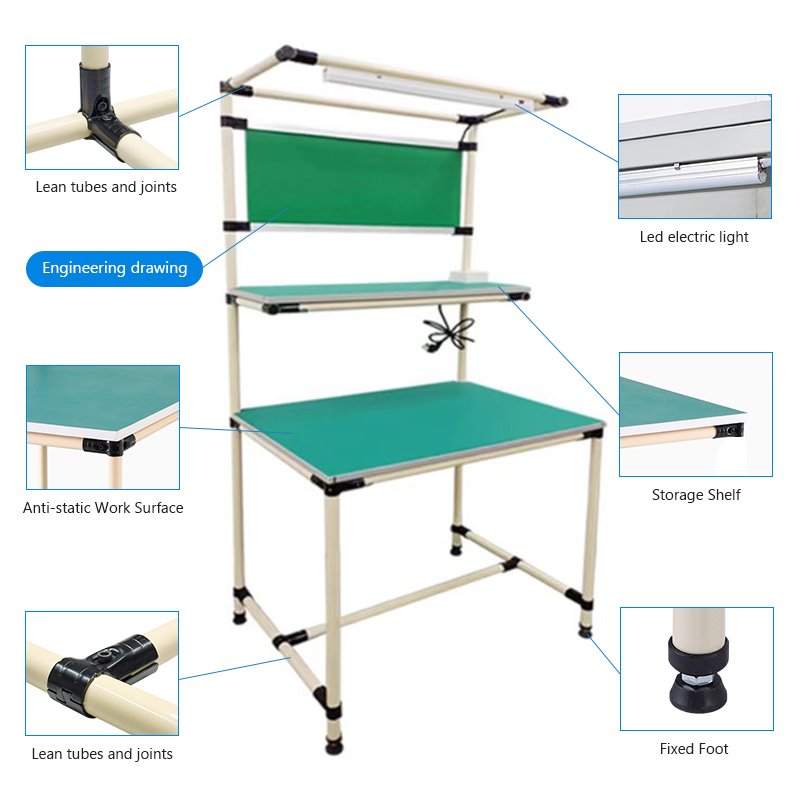

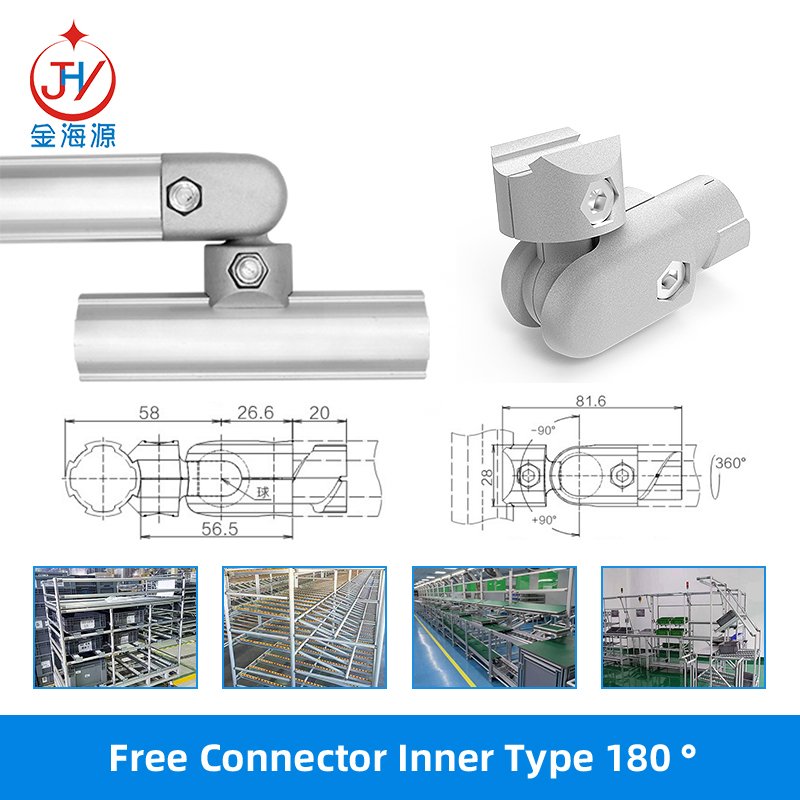

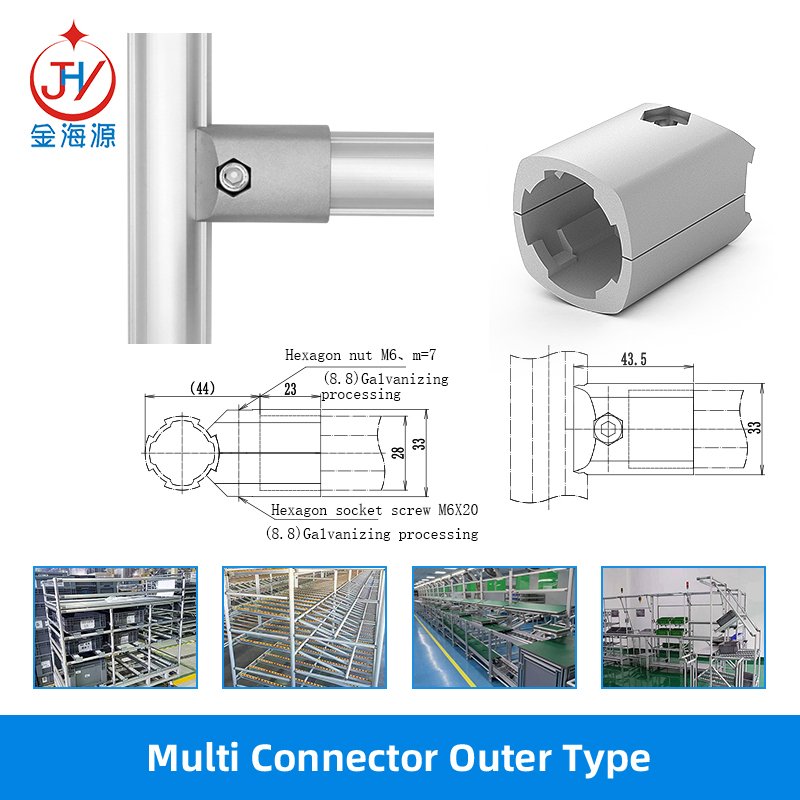

How Are Lean Fittings Connected?

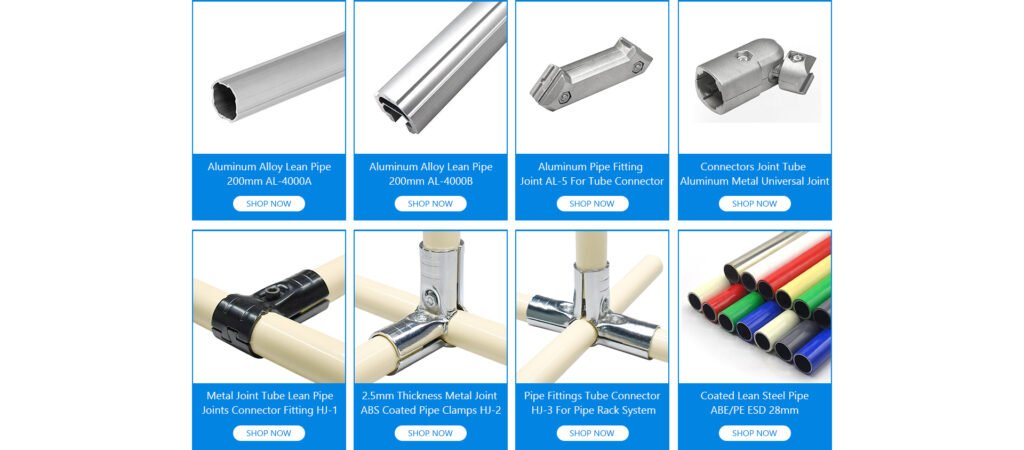

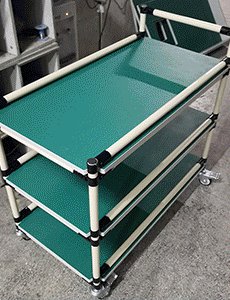

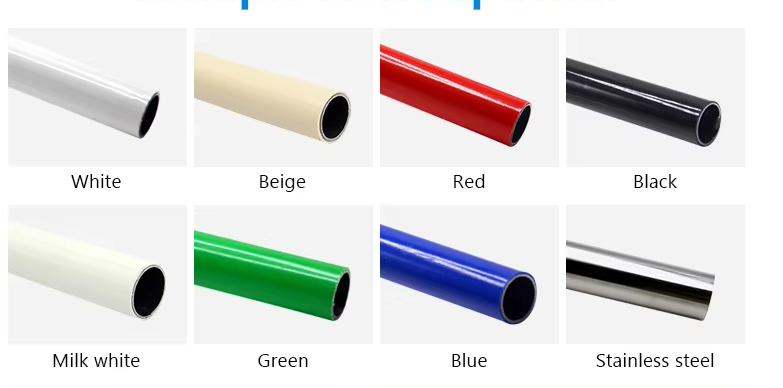

Lean pipe optional accessories refer to the components that can enhance product functions and improve product performance in addition to standard accessories, and different from standard accessories, the use of optional accessories will not affect the use of the basic functions of the product. There are many types of optional accessories, and the optional products […]