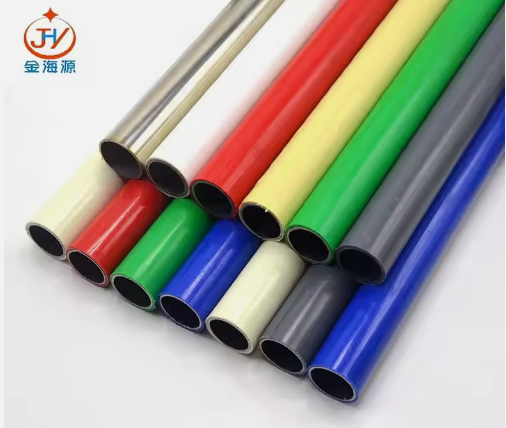

The Lean pipe is also called wire rod, plastic pipe, it is the outside is the plastic layer, the middle is the steel pipe, the inside is the antirust coating composite pipe, the wall thickness is optional, the color is optional.

The use of lean tube is not limited by the industry, and its use is not too high requirements, any industry can be seen in it, because it in addition to the load instructions, do not have to consider too much accurate data and structural rules. It can according to their own special needs to design, build and adjust, is very flexible, building blocks components can satisfy the construction of various structures, need can be zero for the whole, do not need to be whole into zero, convenient mobile restructuring, the disassembly and installation process is very simple, the assembly personnel and no special requirements.

The use of the rods also reduces the risk of injury in the workplace, as the main components of the products are coated with plastic on the outside. Lean tube has the advantage for us to choose it: lean tube is scalable, and it can design new structural products that can meet the current needs through the needs of different products.

Add different production methods or different stations; lean pipe is reusable, and the accessories of wire rod products can be recycled. At the end of the cycle, change the original wire rod and assemble new requirements, which can greatly save cost. Lean pipe is ergonomic, due to the simple and adjustable ability of wire rod products, it is very convenient to adjust the height of wire rod products, so every operator can be in the best working position.